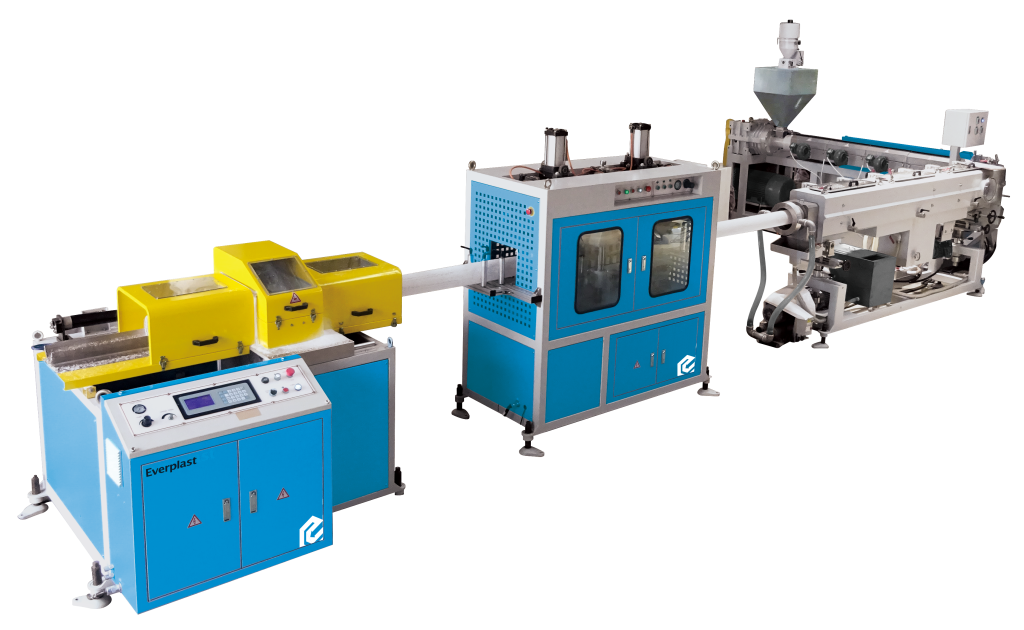

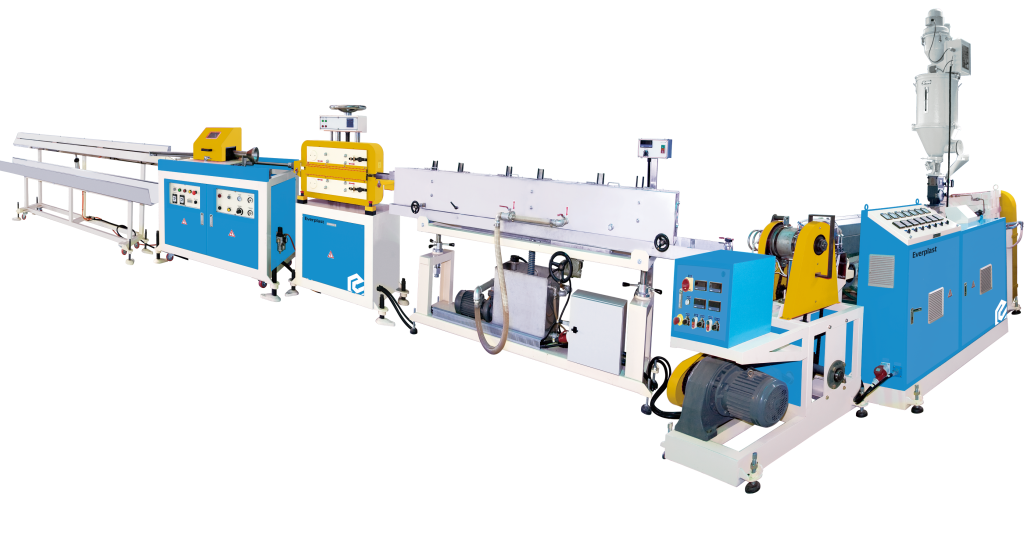

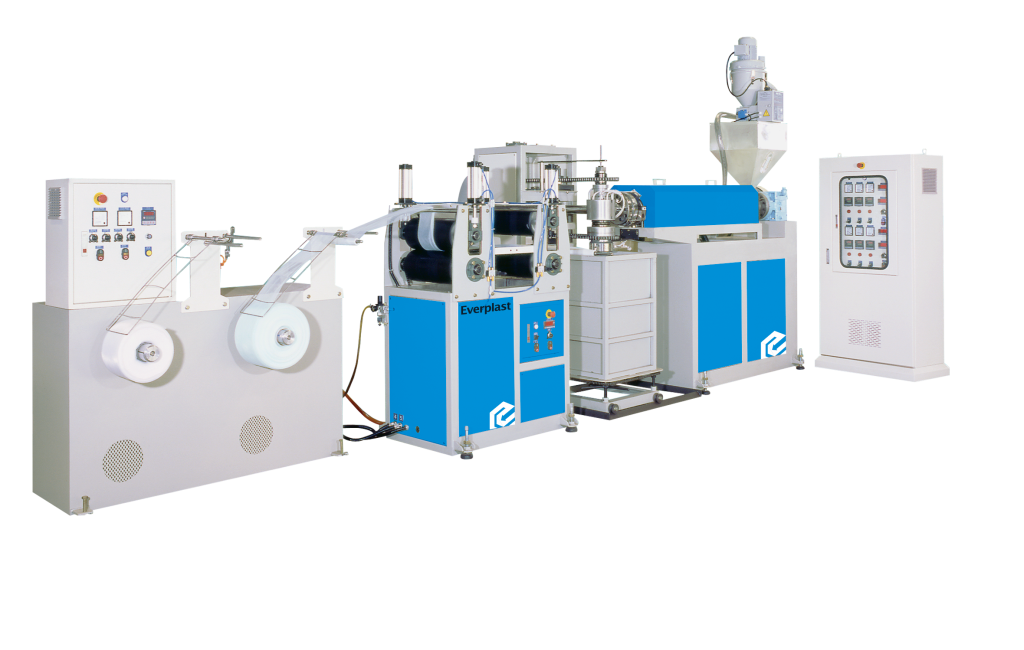

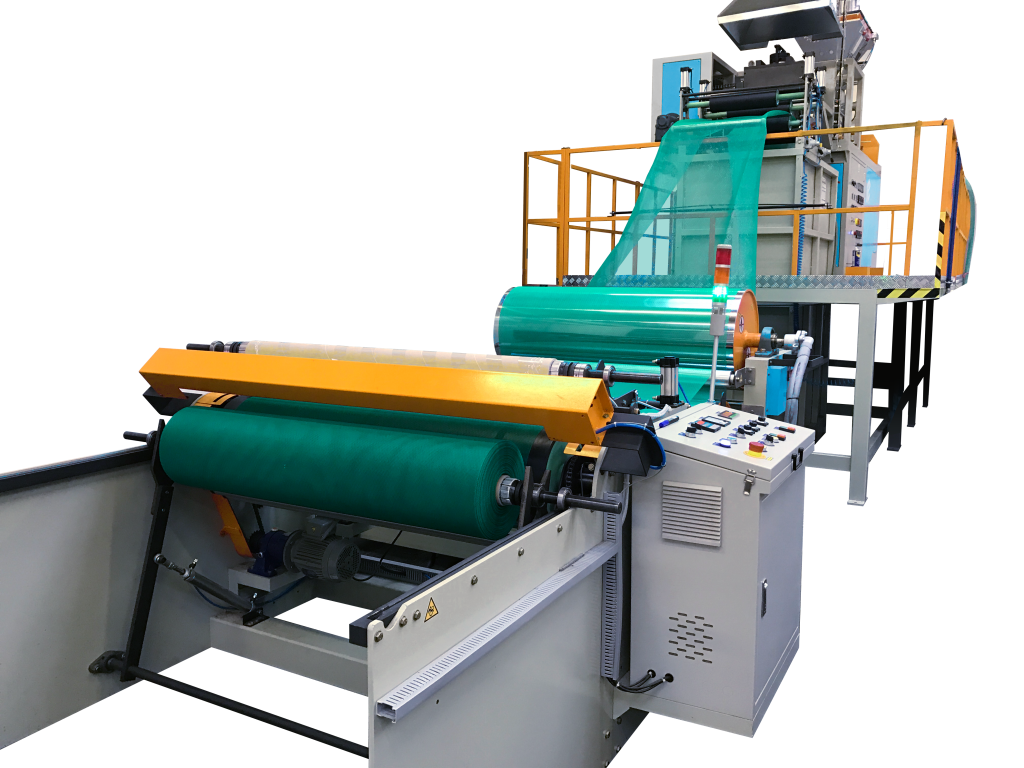

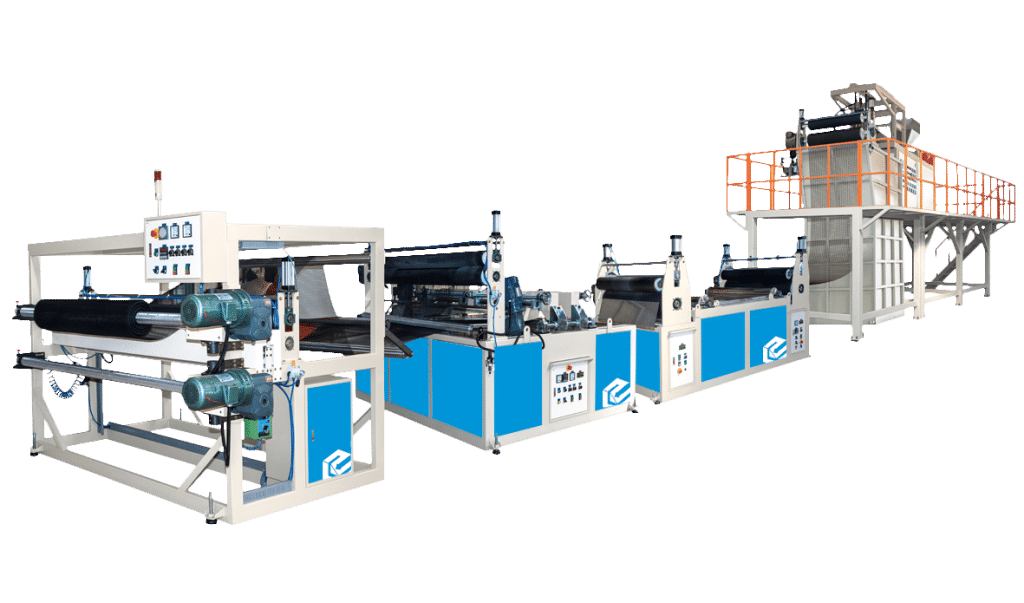

PLASTIC NET MAKING MACHINE LINE

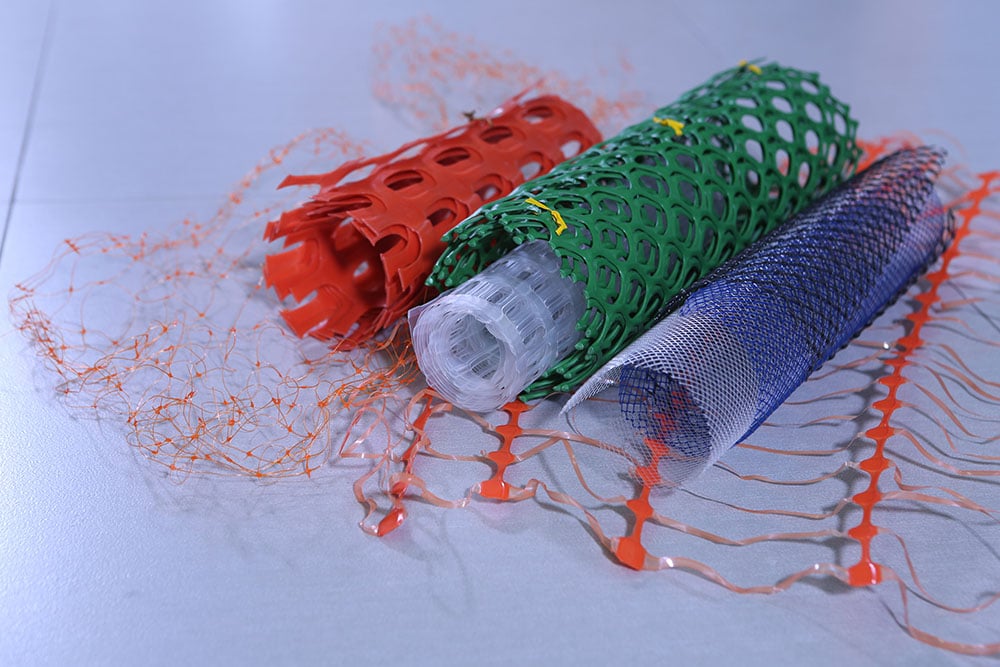

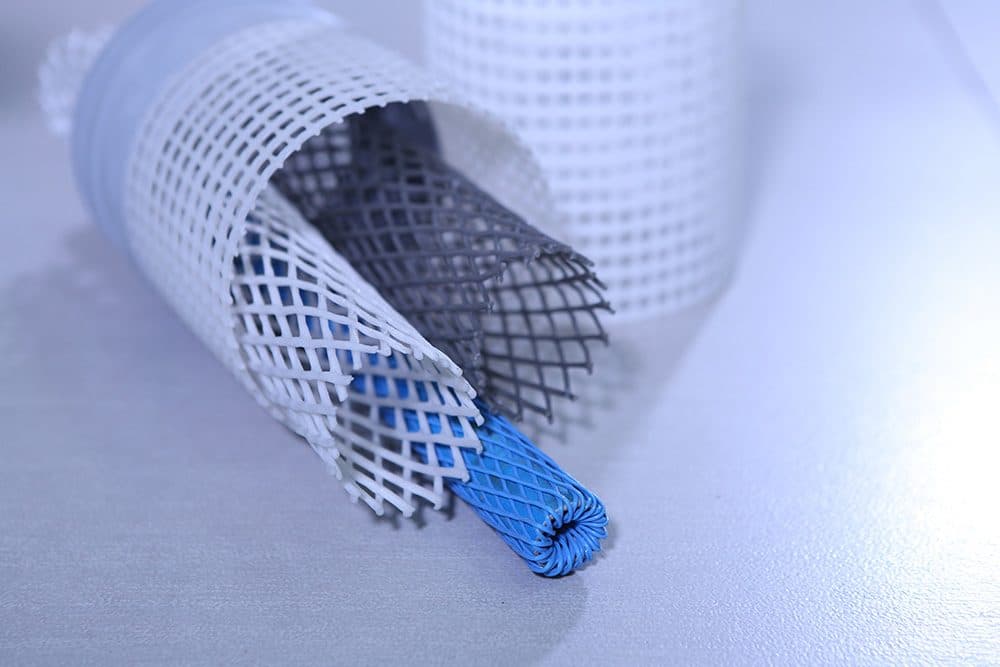

We provide a variety of different applications of plastic net making machine, that includes fruit nets, fence net(Mono-Oriented Net), agricultural buildings to protect networks (Bi-Oriented Net), filters and water resource management…etc.

FEATURES

PE net making machines are specially designed for high production requirements. They provide high productivity, high accuracy, and exceptional fine surface on the nets. The screw is precision machined from high quality alloy steel SACM-1 with nitrogen treated for high performance and duration, ensuring high extruding capacity, automatic temperature control. The entire machine motions are controlled by the high performance controller for convenient operations.

main products

APPLICATION

We provide a variety of different plastic net machine, that application includes fruit nets, fencing, agricultural buildings to protect networks, filters and water resource management…etc.

Material: PP / PE

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.