pipe extrusion machine

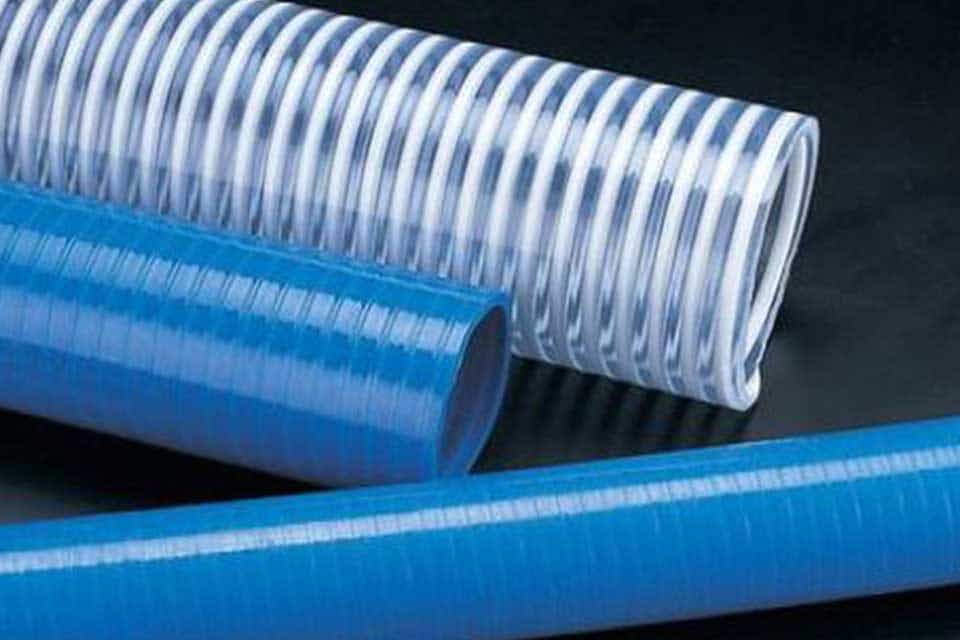

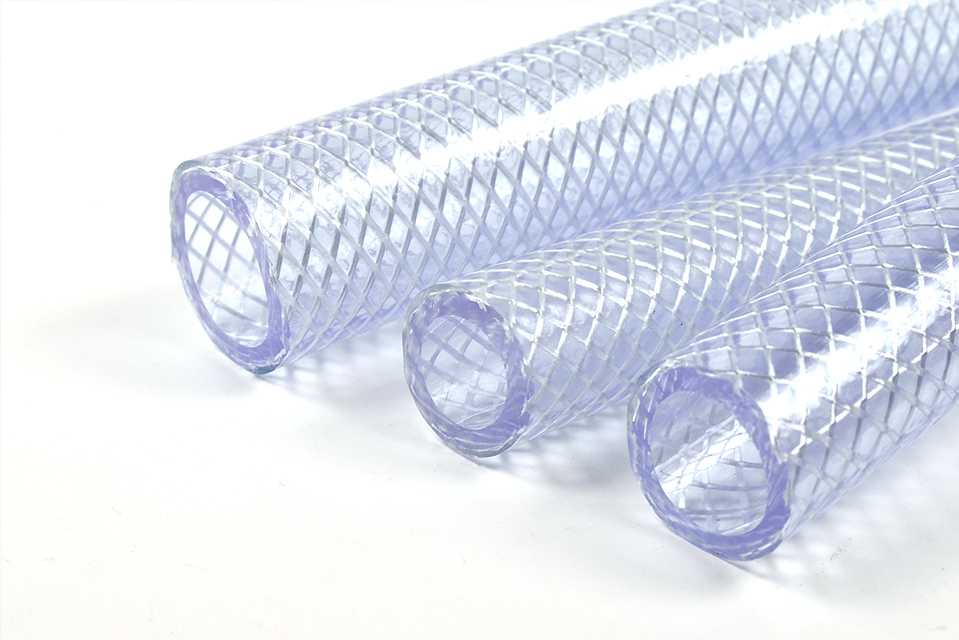

The plastic pipe extrusion machine uses materials such as PVC, HDPE, LDPE, PE, PP, ABS, PS, PC and PMMA to extrude products in accordance to market needs and the characteristics of the plastic materials.

FEATURES

This portion of the production line introduces pipe extrusion, which uses materials such as PVC, HDPE, LDPE, PE, PP, ABS, PS, PC and PMMA to extrude products in accordance with market needs and the special characteristics of the plastic materials. Products manufactured with these machines include construction materials, toys and stationery, furniture and furnishings, medical supplies, lighting decorations and electrical accessories.

Since its funding EVERPLAST Machinery’s production line has turned out more than 1500 extruding systems of this type.These machines turn out products that are well suited to the market and features design that is directly related to the characteristics of the production processes that are exactly right for the plastic materials being used.

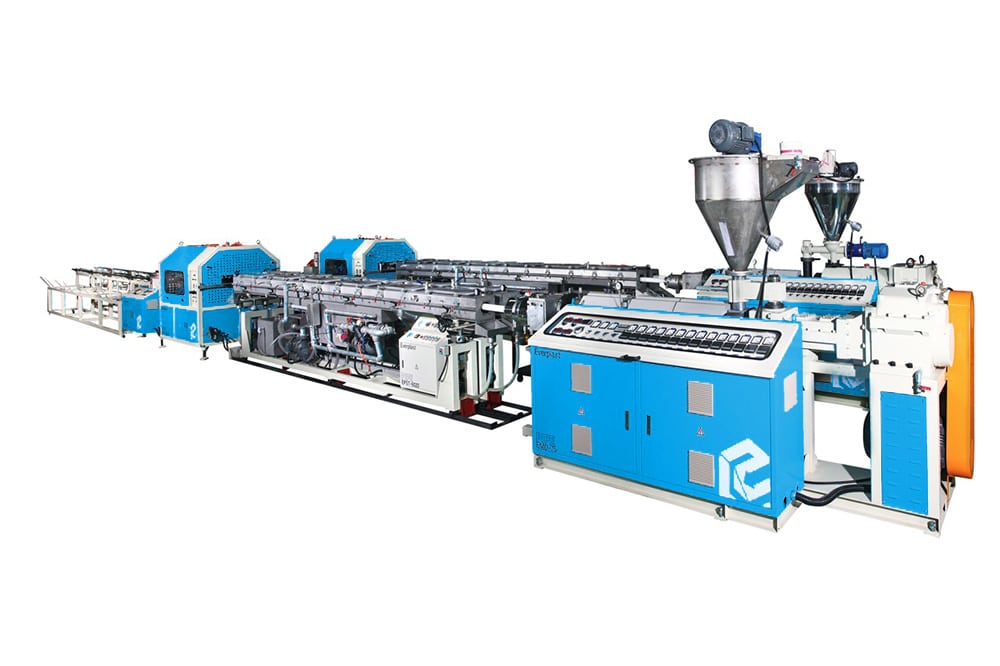

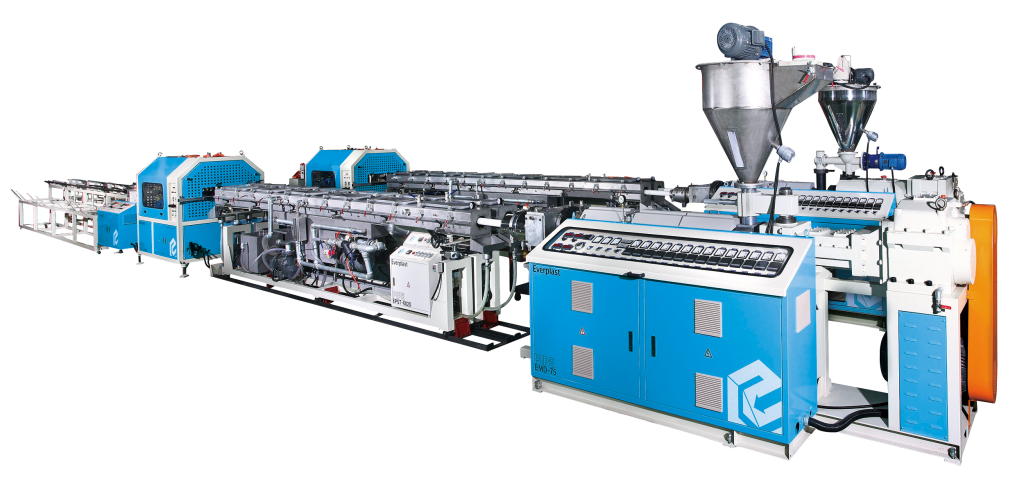

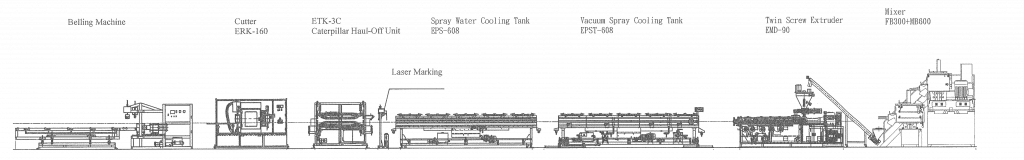

PVC Pipe Extrusion Machine Line

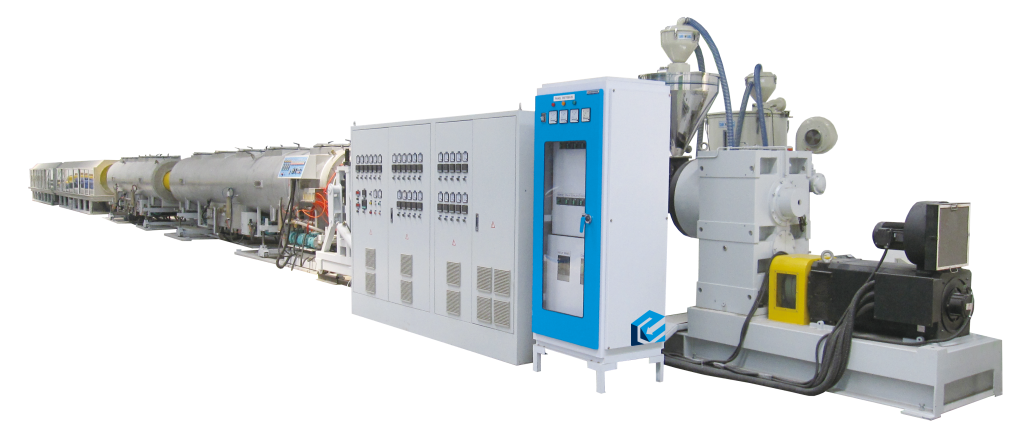

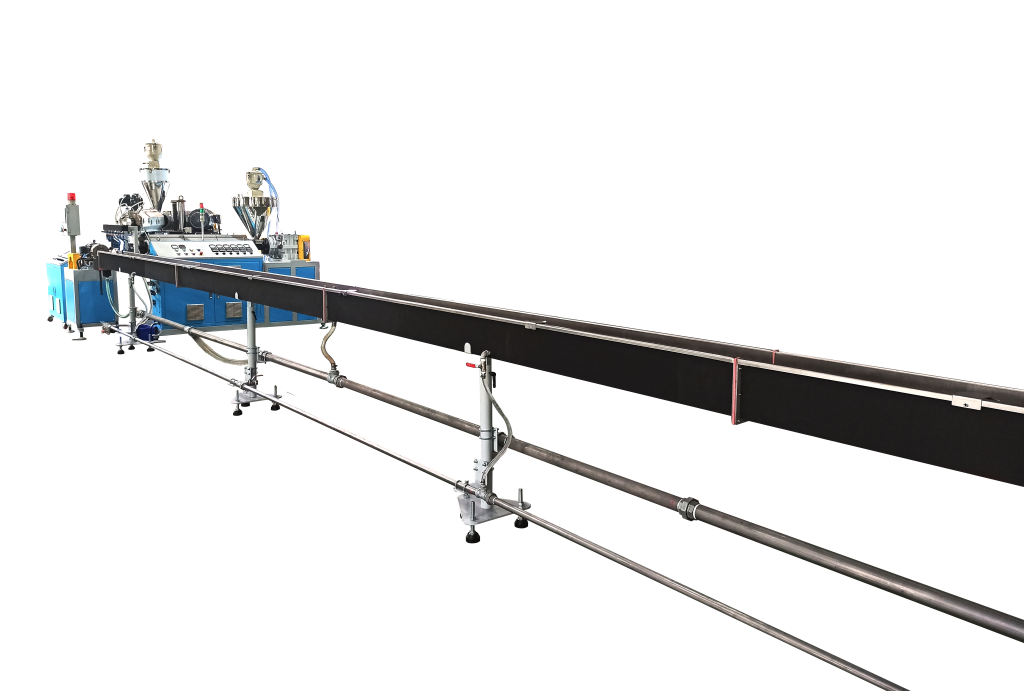

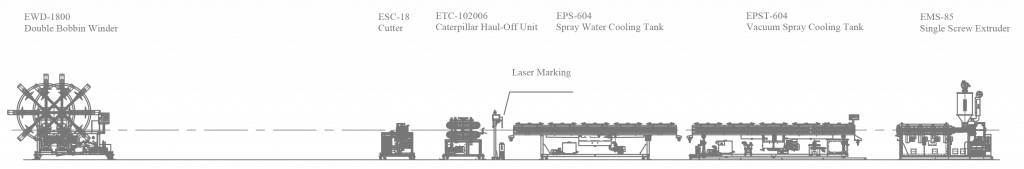

PE Pipe Extrusion Machine Line

- We provide a variety of PVC Pipe Parallel Twin Screw Extruders: EMD-55、EMD-65、EMD-90、EMD-110 and EMD-130.

- We provide a variety of Conical Twin Screw Extruders as well: EMD-55C 、EMD-65C、EMD-80C and EMD-92C.

- EMS-45,65,85,100 and 120, our single screw extruder models are diverse which enable to cover different types of materials and reach different sizes (12mm~630mm) of PVC pipe. The production capacity can be 50~1000kg/hr.

- Our EMS-45、55H、65H、75H、85H、100H、120H and 150H are the extruder series for producing HDPE Pipe, can cover 12mm-1200mm diameter with 10-1000kgs/hr production capacity range.

main products

APPLICATION

The plastic pipe products can be used in a wide range of industries, including pvc pipe, pe pipe, ldpe pipe, hdpe pipe, pp pipe, abs pipe…etc.

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.