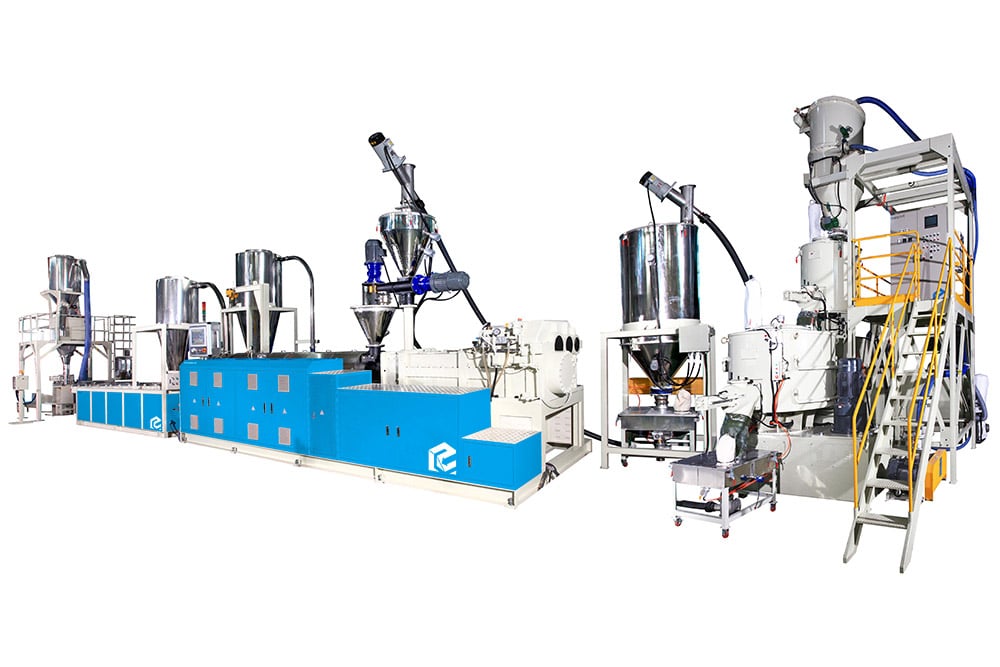

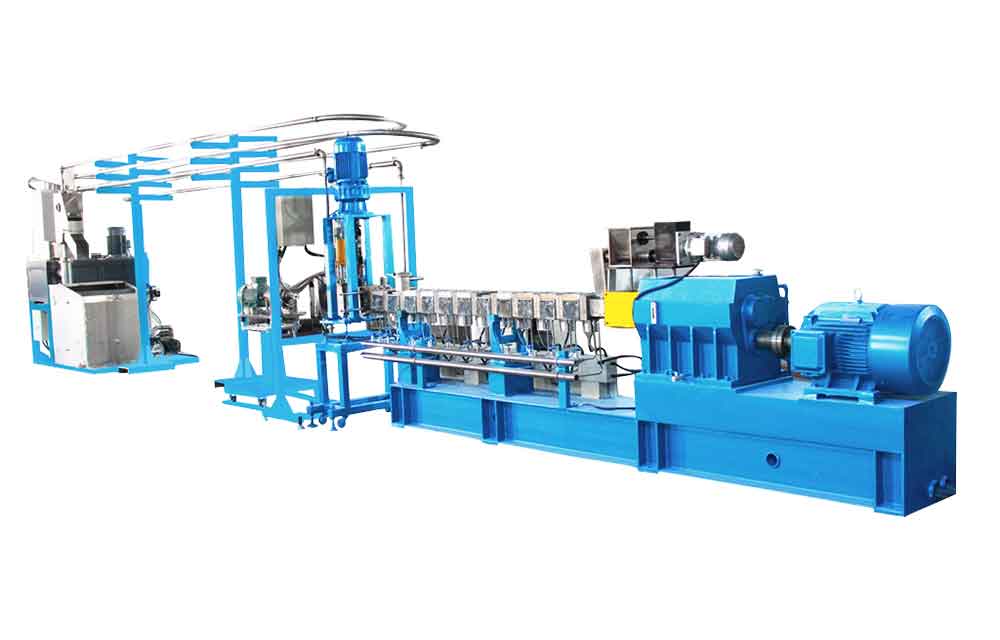

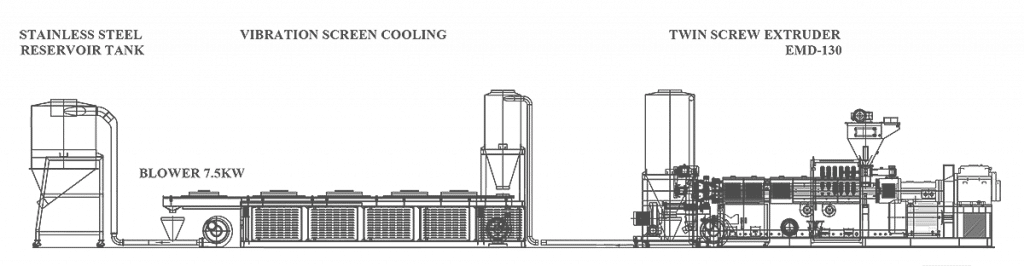

COMPOUNDING & PELLETIZING SYSTEM

All compounding & pelletizing system incorporate proven process engineered feed screw designs with optional venting, side feeding and complete process feed systems for volumetric, gravimetric weigh blending or starve feeding of the materials provided as required.

FEATURES

EVERPLAST offers a complete line of single and twin screw compounding machine and reprocessing extrusion systems featuring extruders designed for the specific application.

All system incorporate proven process engineered feed screw designs with optional venting, side feeding and complate process feed systems for volumetric, gravimetric weigh blending or starve feeding of the materials provided as required.

main products

APPLICATION

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.