PVC 3-layer Transparent Reinforced Hose Production Line / Five-layer Reinforced Hose Tube Extrusion Machine Line

Testing Reinforced Hose Extrusion Line in Russia

Reinforced plastic hoses have many applications in life. They are mainly used for water supply, garden irrigation, air conditioning and heating systems, household, and industrial drainage… etc. to transport fluids, gases or solid materials. They are soft, light, and durable.

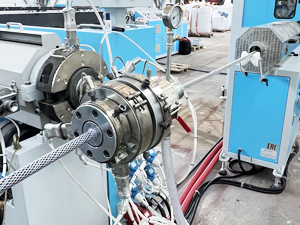

Everplast Machinery went to the Russian customer’s factory for trial operation in August 2023. Our customer’s company mainly manufactures reinforced hoses. There are 4 hose production lines in one of the factories. Because the customer hopes to provide stable quality and production capacity of the production hose, we chose Three-layer/five-layer reinforced tube extrusion production line produced by Everplast Machinery.

The two reinforced tube extrusion lines ordered this time adopt the size of EMS-75 75MM extruder, with a capacity of 40-100 kg/hour (depending on the size of the product and the raw materials used). In addition to the second half of the equipment – water tank, the extraction Machine, pneumatic cutting table and winding machine, the main yarn wrapping machine adopts belt drive, the maximum size is 12-50 MM, has an independent control panel, the braking device is connected to a microcontroller design, and the yarn speed reaches 200-350 RPM. The yarn-splitting disc is designed with 16 left-biased yarns + right-biased: 16 yarns combined with 4 straight yarns, allowing the yarn-wrapped tube to be extruded, and the finished product has better blasting pressure resistance, and the machine protective cover design makes the operation safer. Secondly, in order to facilitate the operation and production, we designed a PLC synchronous control system, which can synchronously control 3 extruders + 2 extraction machines + 1 yarn wrapping machine, local/remote control, easy to operate and adjust.

When manufacturing reinforced hoses, the softness and hardness of the plastic raw materials, and the temperature and volume of the water will all affect the production stability. The extrusion size is 17.8mm five-layer reinforced tube, and the line speed exceeds 16m/min. Everplast has more than 30 years of accumulated extrusion experience and provides professional extrusion methods. By thickening the inner tube, there is more room for improvement in co-extrusion. Because multi-layer hoses are not easy to produce and require more practice and familiarity with machine mold adjustment, Everplast provides another 2 days of focused training services, hoping that customers will be more familiar with the operation. During the test run, the customer was very satisfied with the performance and service of Everplast’s machines. The customer is optimistic and plans to consider purchasing more machines from Everplast.

Everplast Machinery provides one-stop service for plastic extrusion equipment and also provides Reinforced Hose Recycling System, welcome to contact us soon!

Material: PVC

VIDEO

EMS-55 Reinforced hose extrusion machine line

RELATED PRODUCT

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.