PVC Door panel

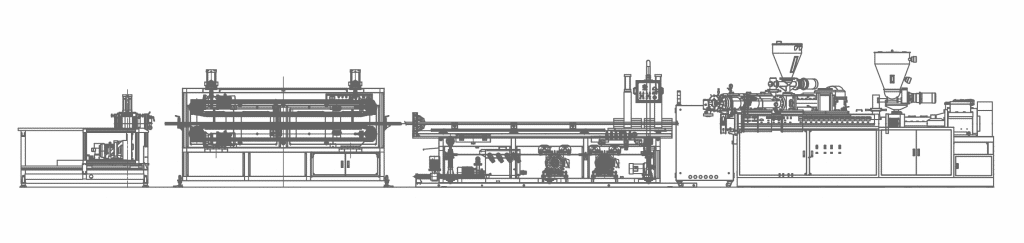

machine line

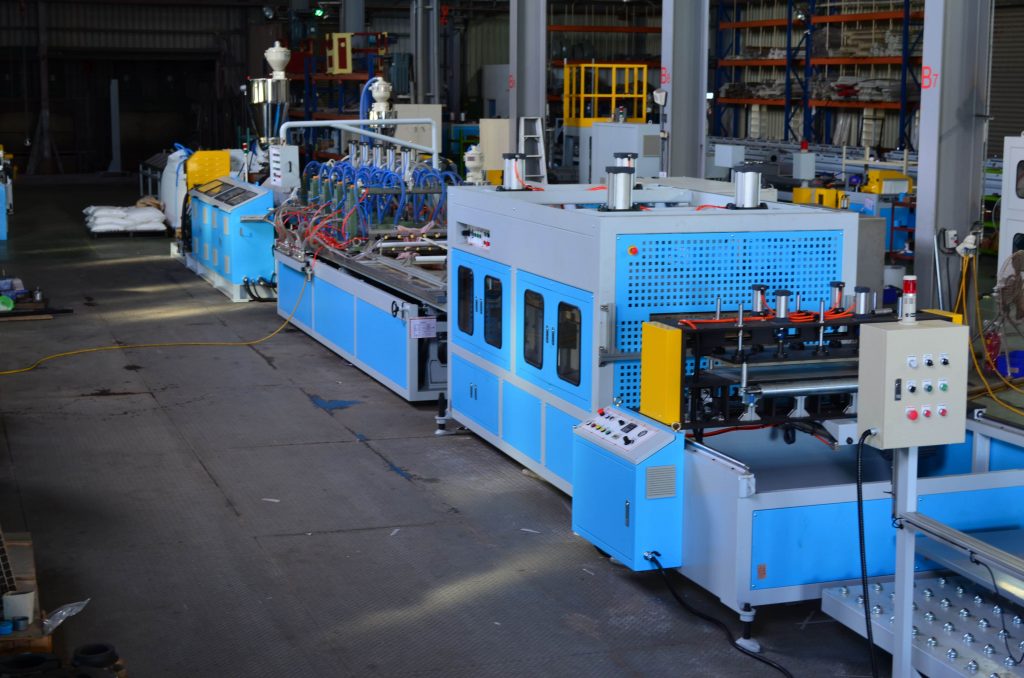

Everplast has machines all over in the Philippines, Indonesia, India, Thailand, and Russia. The raw material of the door panel machine line is PVC, and the models are EMD-90, EMD-110, and EMD-130. With the design of the parallel twin-screw extruder, the output of each machine line ranges from 150-350 kgs/hr. Also, it’s based on customers’ needs to formulate output and reduce the waste of raw material output.

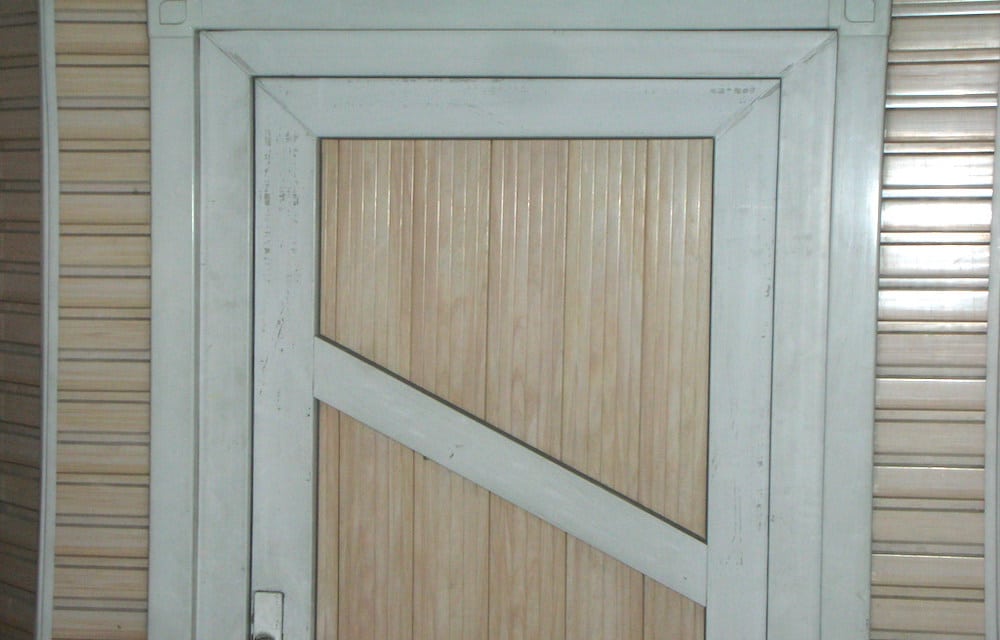

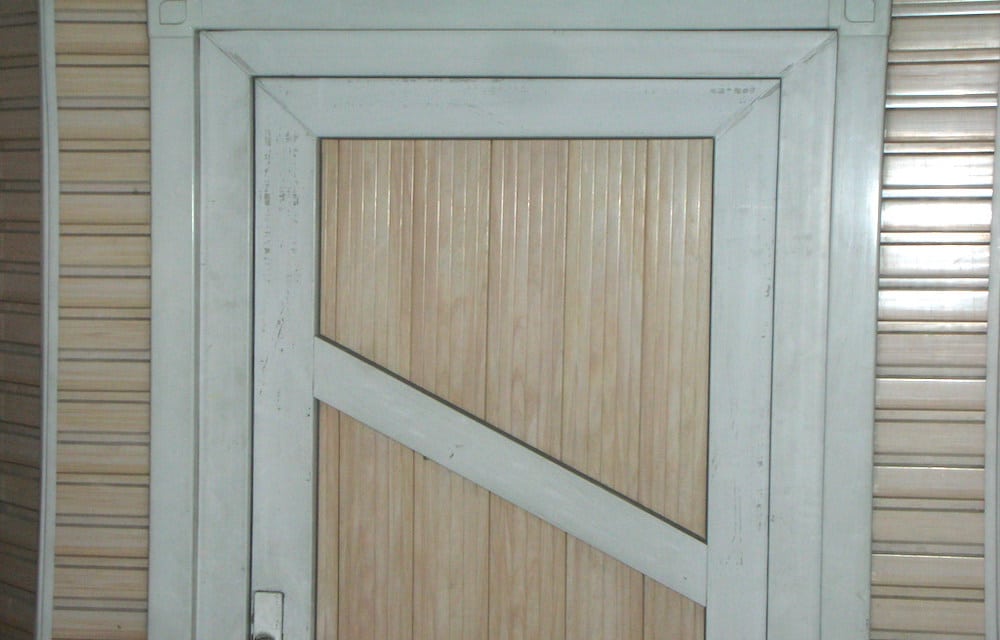

“Door” has an important existence in a family, a company, etc. Especially the door produced by Everplast, which helps keeps you safe and secure.

Door Panel Machine Line:

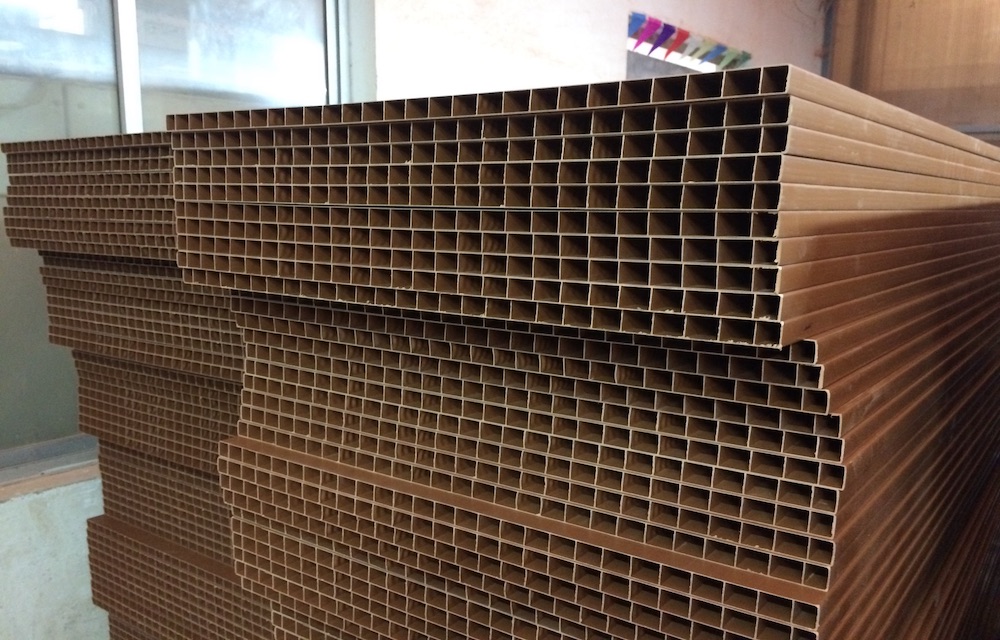

The use of “doors” is ubiquitous. The plastic door panels produced can be extruded in five specifications of 600, 700, 760, 815, and 900 mm, which can be used in various spaces.

APPLICATION

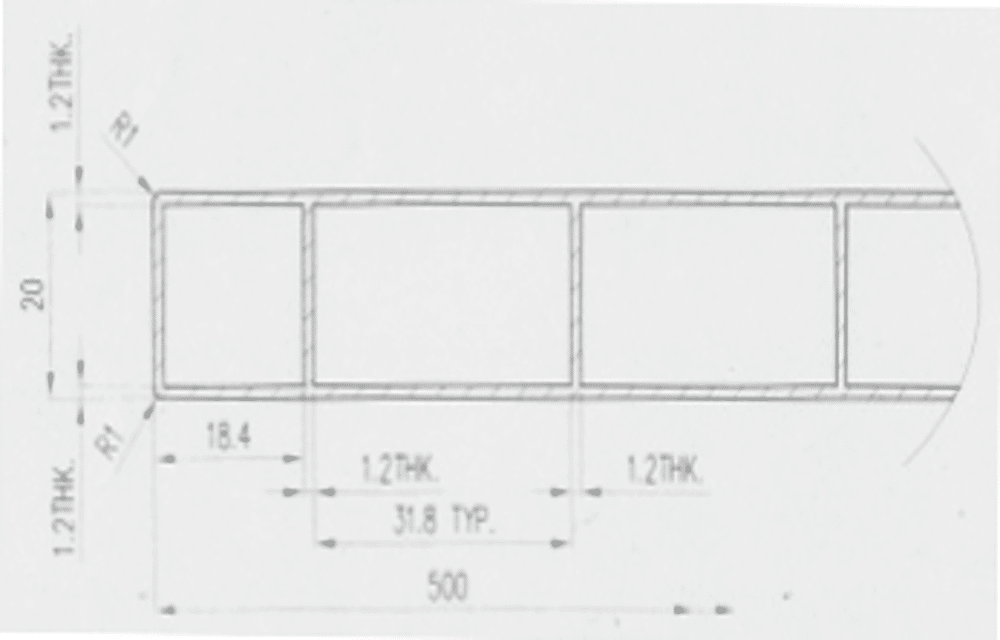

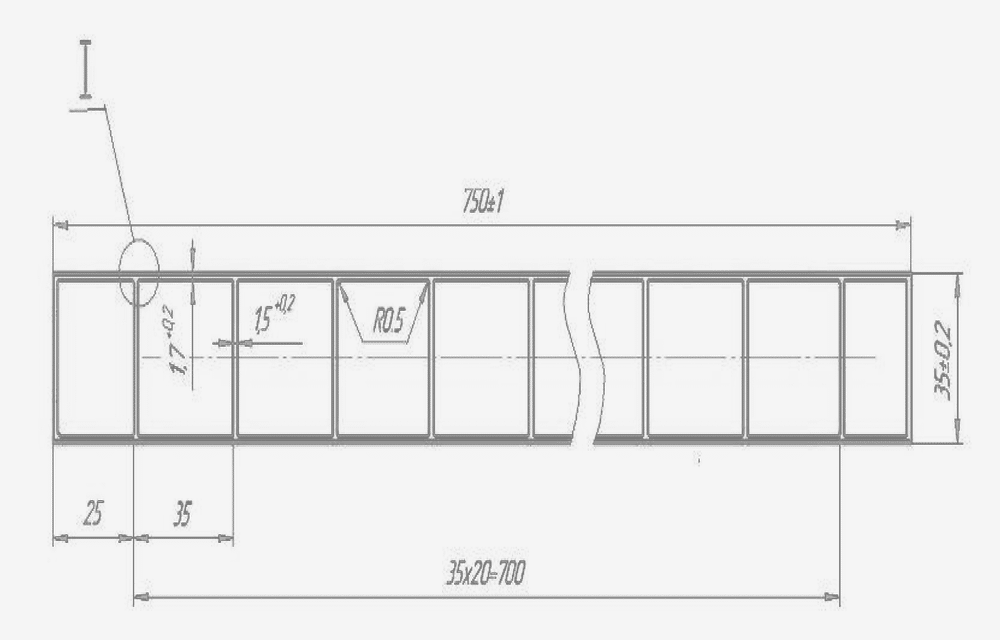

FEATURES

Here are several market differences of this door panel machine line:

1. During the design process, it can be matched with printing equipment to produce patterns.

2. In production, cutting is driven by ball screws to achieve chipless cutting of finished products and precise section cutting.

3. When production is completed, it enters the door-type cooling water tank with special air and water separation.

Besides, the machine itself has a semi-automatic hydraulic lifting type aggregate design, and the upper ball design is for the ease of aggregate packaging. Finally, one of our special features is that it can extrude double-layer door panels.

Everplast manufactures machines that tailor closely to customers, which helps achieve accurate production and save customers time and raw material costs.

SUCCESS STORY

PVC Door Panel Extrusion Machine Line

READ MORE…

Related Products

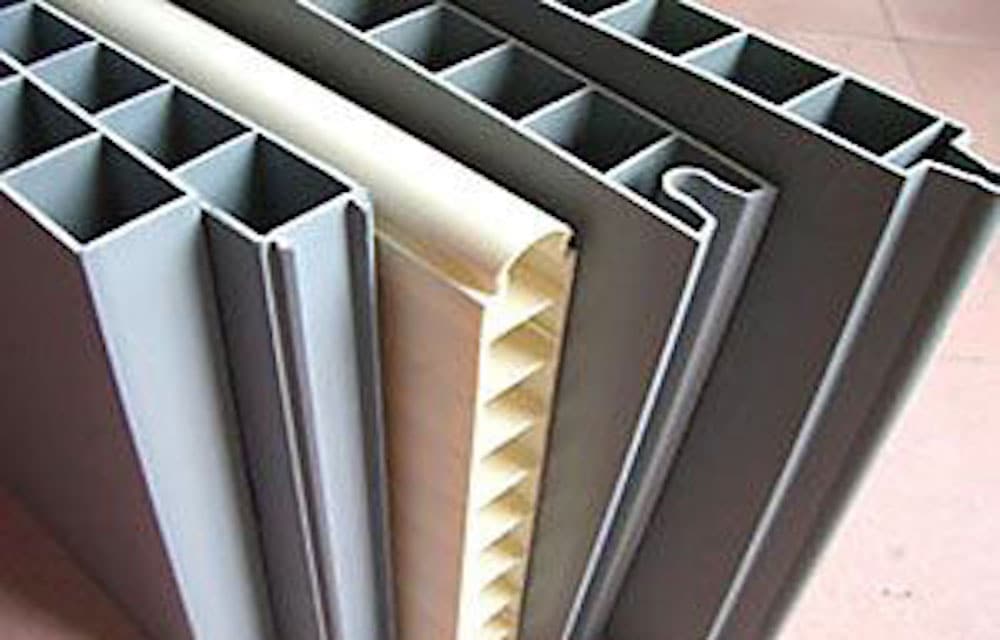

Profile Extrusion Machine Line

READ MORE...

Parallel Type Twin Screw Extruder Machine

READ MORE…

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.