machine line

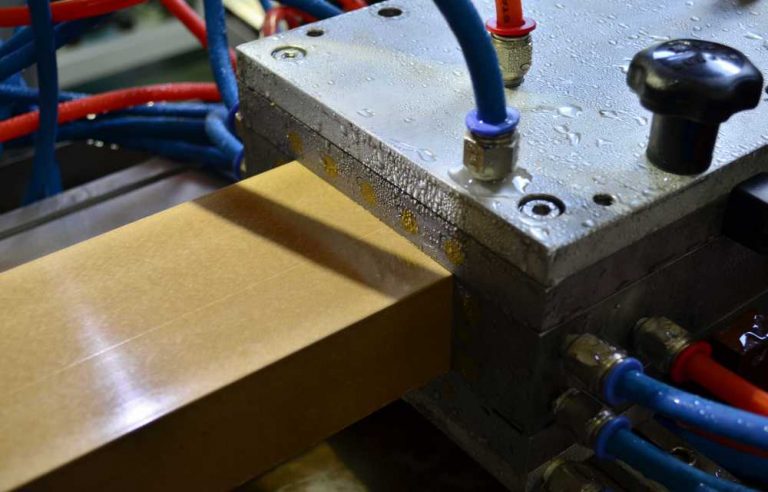

PVC Wood Base products appear everywhere in our lives. Most of the products produced by WPC raw materials are used in building materials, such as a house, plank roads, decking, wall panels, fence, railing, bench, etc.. WPC with its high quality and durable characteristic could perfectly replace real wood and other material. WPC provides many benefits as strong structure, sound insulation, water-proof, anti-corrosion, UV-resistant, resistant against fungi and insects, anti-fire. EVERPLAST provides WPC extrusion total solution for the market needs.

WPC has been used in various application furniture, garden, building, roofs, etc with high quality but very low and cheaper maintenance cost. The proficient surface treatment not only provides a unique look to the WPC boards but also gives a ravishing look to the boards.

WPC compound consists of plastic resin, natural wood, stabilizing agents, modifiers, filler, foaming agents and etc. Good formulation produces such a high quality product. The possibility of using recycled resin mixing with a variety of natural fibers like wood dust/ Gypsum/ Rice husk/ Nutshell/ etc.. A upcycle process makes local waste source into valuable products.

APPLICATION

FEATURES

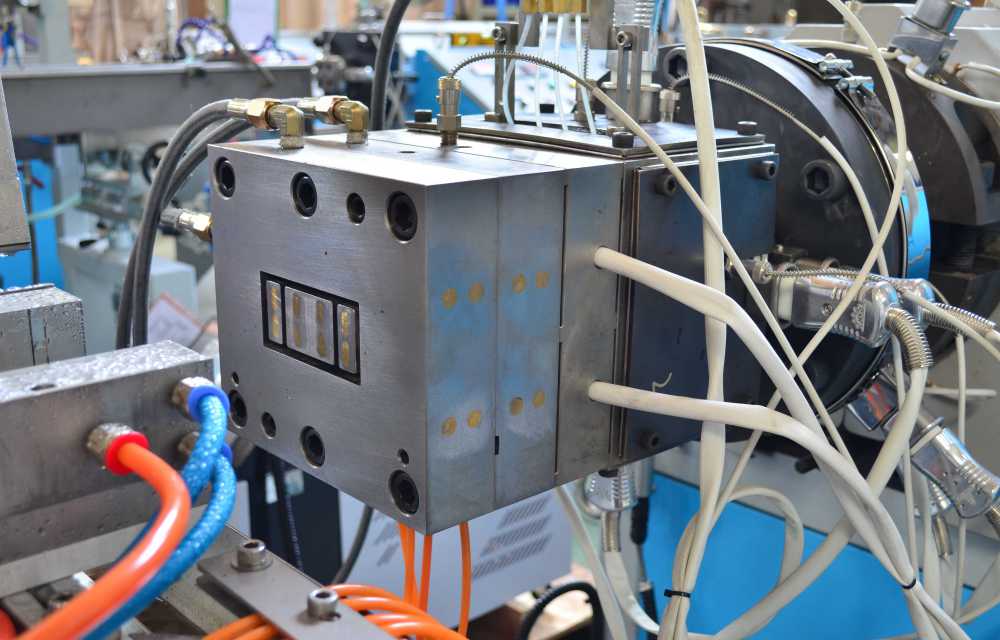

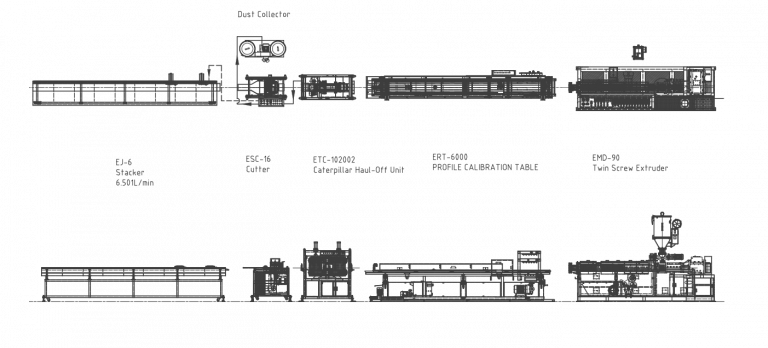

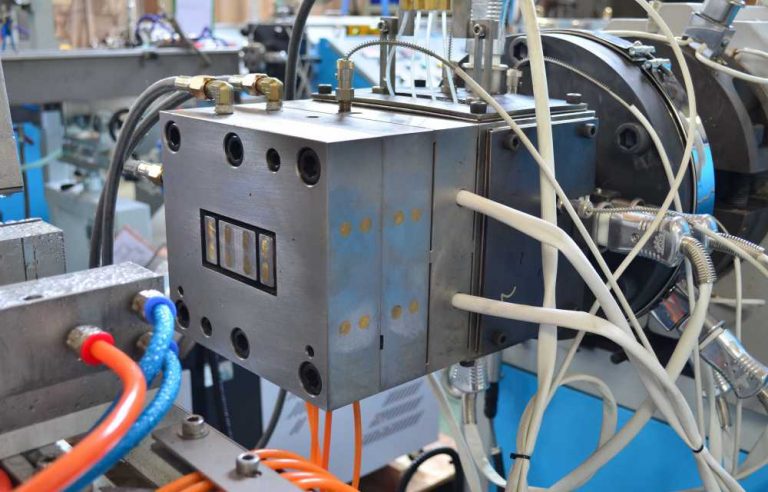

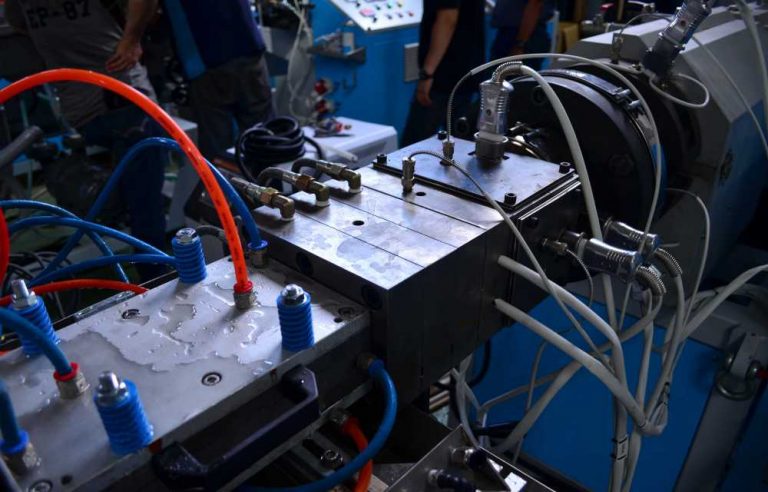

Everplast (Taiwan) rolled out the EMD-90 parallel twin screw extruder, which can produce 100-250 kg of WPC per hour. The controls of temperature, material vapor exhaustion, mould tuning are critical. Most of critical machine parts such as screw, barrel, gear box are highly precisive controled, enable highly stable of production. Our most advantage is that we combine the material characteristic with our machine, moulding to fulfill customer demand and requirement.

Everplast has always insisted on standing on the same line with customers, providing customized services, solving problems, providing the most human friendly operation. With various experience and know-how in material and mechanical, Everplast is your reliable partner and also a consultant.

Success story

WPC Foam Board Machine Line

READ MORE…

EMD-75+EMS-45 WPC Machine Line

READ MORE…

EMD-75 WPC Extrusion Line

READ MORE…

Related Products

WPC Extrusion Machine Line

READ MORE…

Parallel Type Twin Screw Extruder Machine

READ MORE…

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.