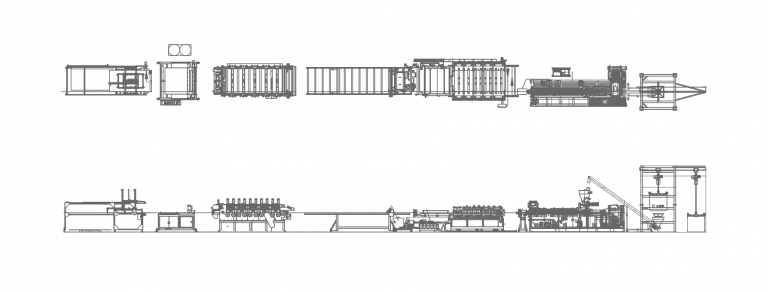

machine line

Do you know that WPC Foam Board are everywhere in our lives? Today, let Everplast give you an insight into our machine lines!

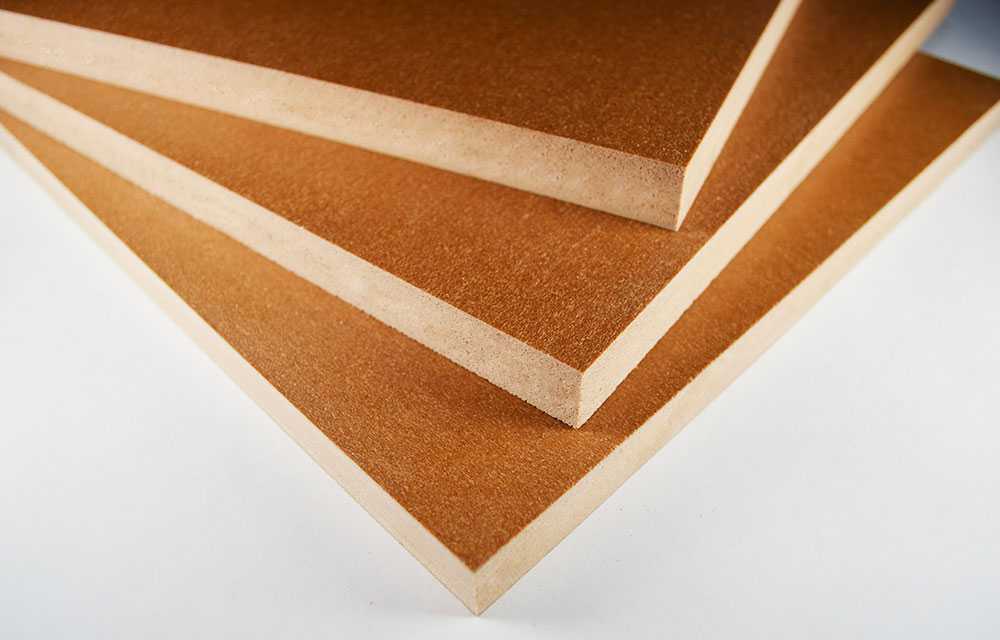

Most of the products produced by WPC raw materials are used in building materials, such as plank roads, wall panels, etc. Different plastics produces different textures and uses PVC CELUKA furniture products that often appear in our daily lives.

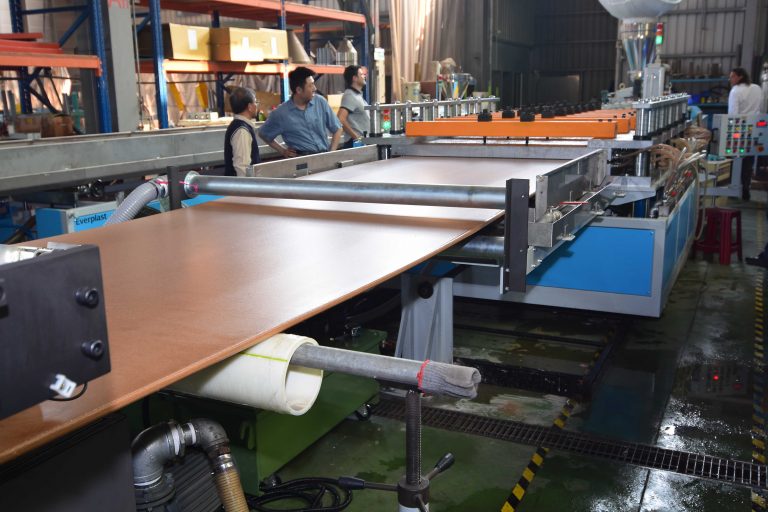

Everplast rolled out the EMD-110 parallel twin screw extruder, which can produce 200-400 kg of PVC foam board per hour. The product specifications are 2440x long 1220x high 18mm and are used on building wall panels, furniture boards, etc.

The finished product will be more complete and have higher quality, if the PVC powder, calcium carbonate, rice husk mixed proportion formula is used in the extrusion process; we can also control mold and machine temperature at all times, which helps solve the phenomenon of orange peel on the surface of the finished product; the product’s dehumidification function determines the output quality, so there are dryers and hot air fans to effectively control the moisture content of rice husk powder; finally by reducing the screw speed and increasing the feeding speed to reach an average output, the surface of the extruded finished product will be smooth and delicate.

APPLICATION

FEATURES

The EMD-110 parallel twin-screw extruder machine features the convenience of a human-machine interface operation. The special flow channel design of T-shaped molds and two-in-one joints provides customized services. In terms of techniques, 1. The material tube vacuum pumping system pumps out excess water vapor to improve product quality. 2. Provide complete equipment, including automatic mixing and cooling systems, capable of high-speed production. 3. Cooling mold fixture is easy to operate with different thicknesses. Taiwan Everplast has always insisted on standing on the same line with customers, providing customized services, and solving problems.

Success story

WPC Foam Board Machine Line

READ MORE…

EMD-75+EMS-45 WPC Machine Line

READ MORE…

EMD-75 WPC Extrusion Line

READ MORE…

Related Products

WPC Extrusion Machine Line

READ MORE…

Parallel Type Twin Screw Extruder Machine

READ MORE…

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.