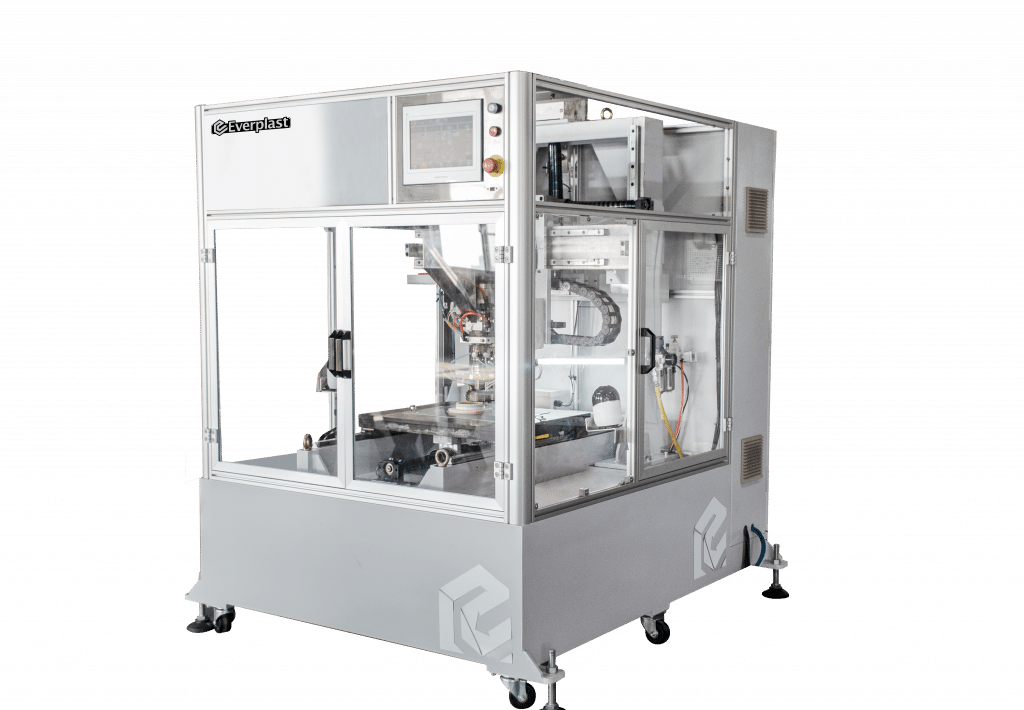

Pellet extrusion 3D printer

Everplast have devoted ourselves to developing Pellet extrusion 3D printer. Our ultimate goal is to develop and fabricate various kinds of Pellet extrusion 3D printer and satisfy all the requests from different customers. Meanwhile, we would collect and enrich the forming database to assist our customers in multi-application. We welcome all the inquiries from every end users and verify the speed and accuracy of our 3D printer. Compared to filament 3D printer, we could save 30% to 70% printing time by accelerating the printing speed.

Speed and accuracy

Save 30%-70% time than a strip 3D printing.

Various printing materials

The advantage of using pellets is that we could use various materials, even mix different materials together for printing. Also it could be applied to bigger, more complicated, even special function objects.

The adoption of extrusion system

By extrusion process, we could change screws and nozzles in compliance with different materials and particle sizes and expand wider applications. Changing screw & nozzle could be done within 20 to 30 minutes which saves more time than filament-printing type.

Technical film

In order to solve the problems of FDM 3D printers, such as a lack of variety in materials, limited applications and time-consuming process, Everplast have presented our Pellet extrusion 3D printers to the markets. Not only accelerate the printing speed, enrich the variety in materials, broaden the applications, but also equip patent & exclusive nozzles to strengthen both the speed & accuracy in printing. Everplast expect the new pellet extrusion 3D printers become an industrial revolution product in this field since we have received orders from customers in European and will strengthen our promotion to the fields in automotive parts, castings, special molding, prosthesis and large figurines.

Material database: ABS, PC+ABS Alloy, PC, PA, PA+ABS Alloy, EVA, WPC, TPV, Fe+PA12

SEND INQUIRY TO US

To provide with better services, please fill out the form below or +886-6-2014846