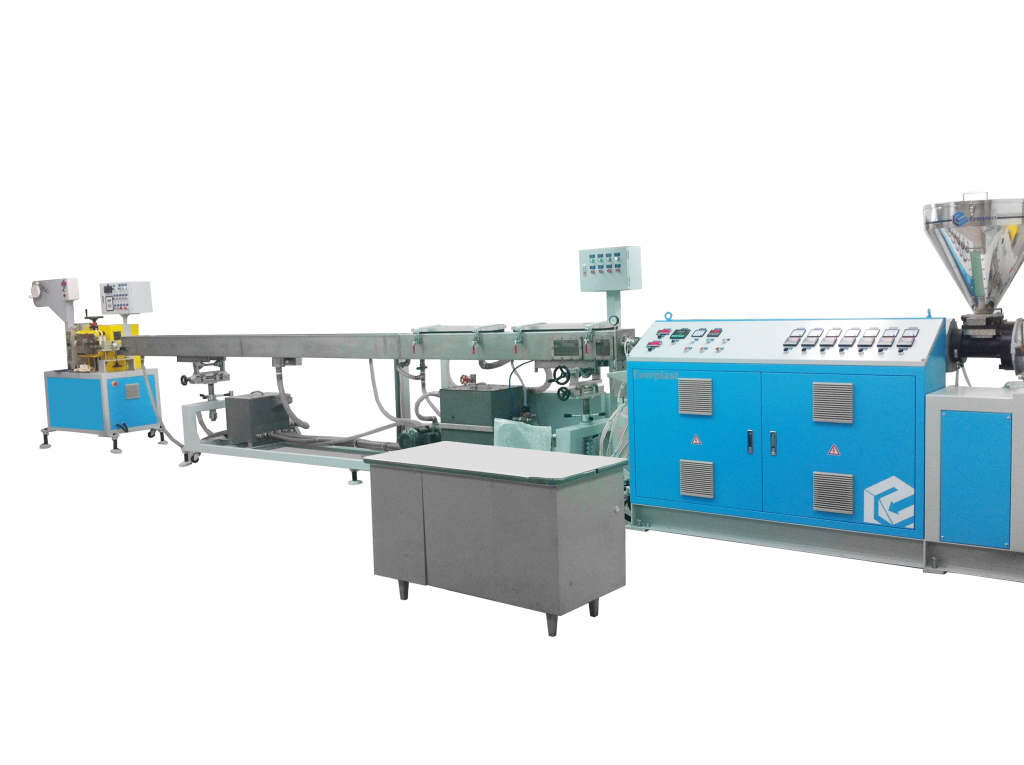

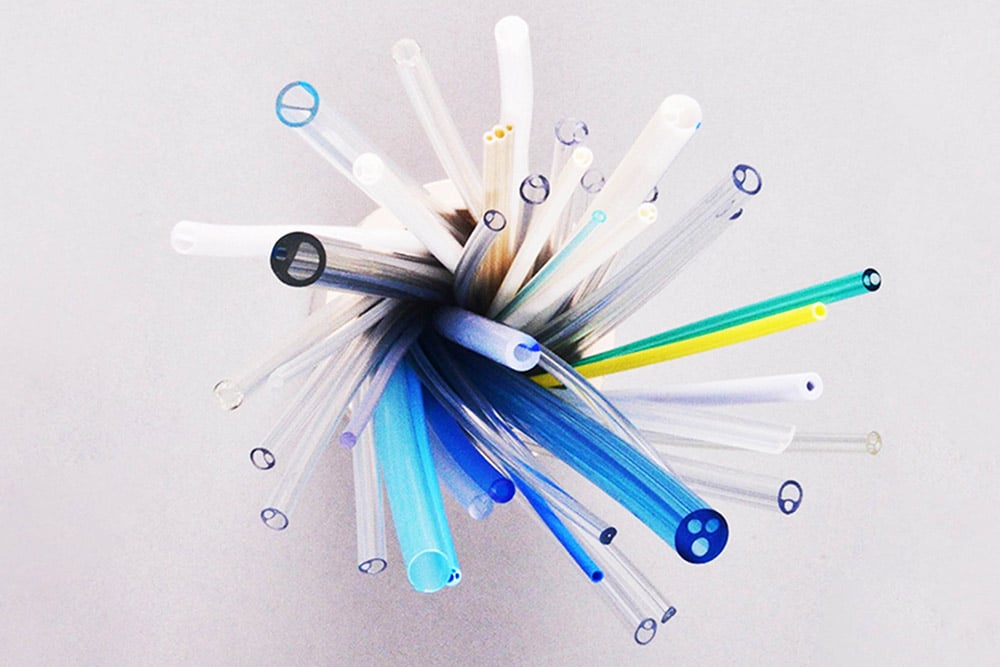

medical tubing equipment

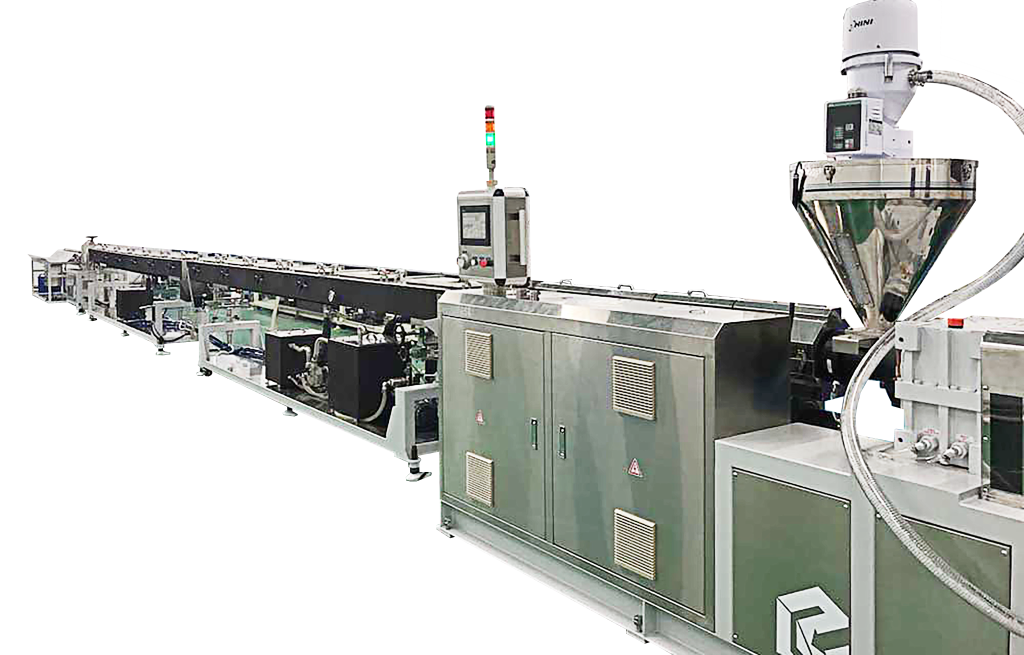

Everplast Taiwan has many different kinds medical tubing equipment for meeting different requirement, EMS-35, EMS-45, EMS-65, EMS-75 and others, Everplast’s machine can be for the different raw material (PVC/PE/TPU/PP/POE/EVA/FEP/PEEK…) for meeting different customer’s requirement.

FEATURES

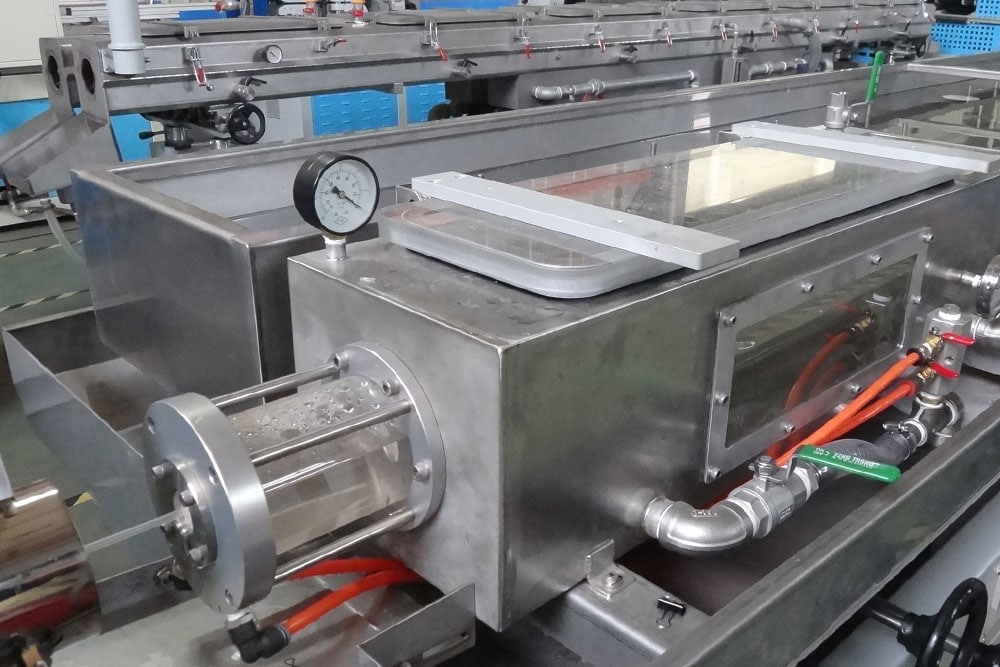

.ANTI-VIBRATION DESIGN OF THE MICRO-VACUUM WATER COOLING TANK

To meet different tube sizes produce at high speed and stable dimension, also water cooling tank can be customized to meet different customer’ requirement.

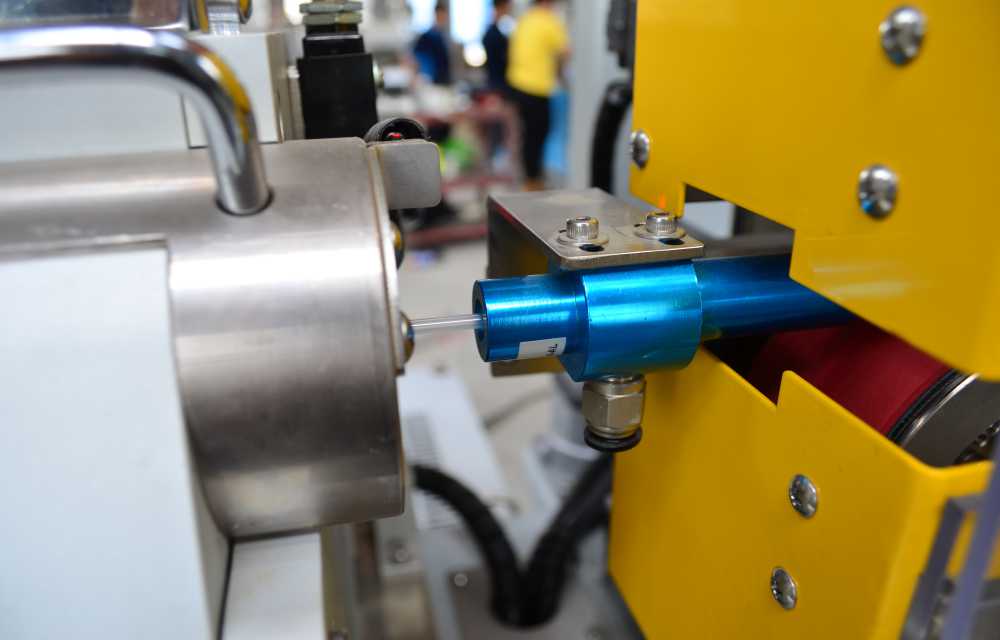

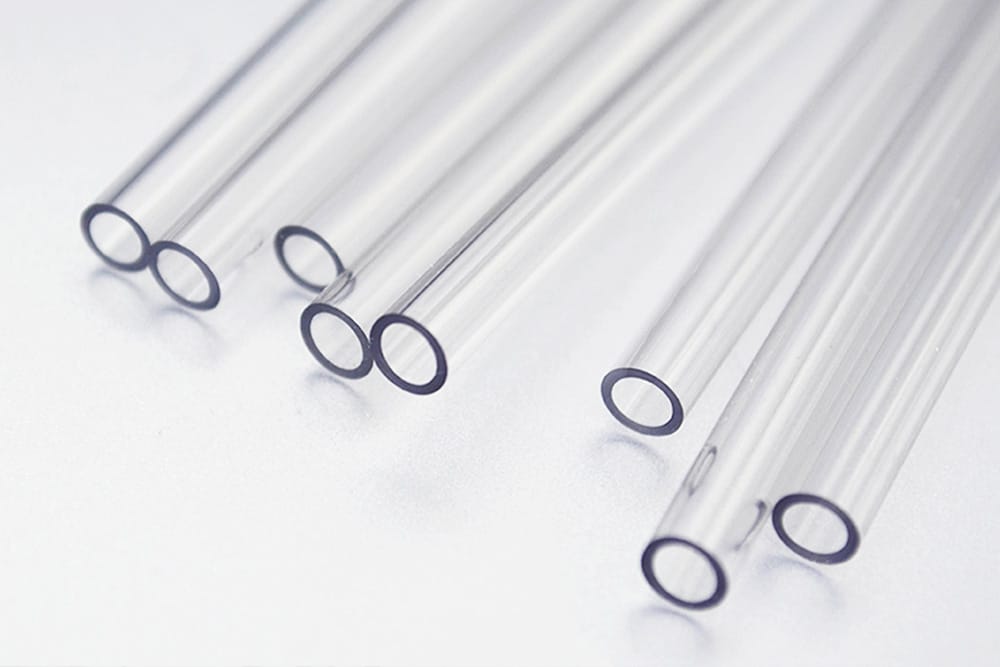

.LASER DETECTOR

For dimension checking, recording, can be on line checking outside diameter, control production record, tolerance stability… all of them are meet medical grade requirement, machine also equipped with fly cutter for tube cutting to reach required length.

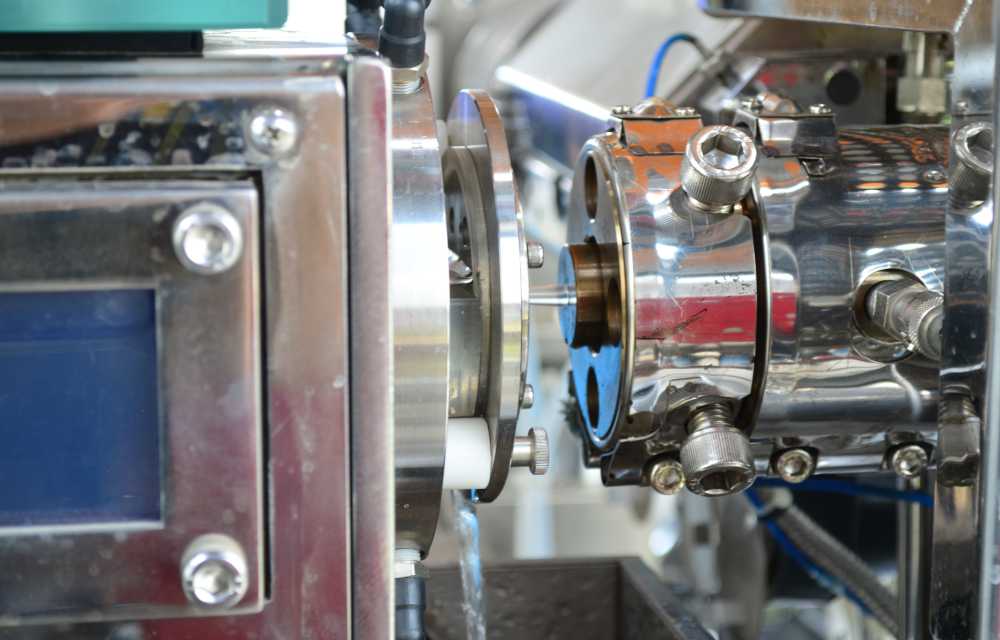

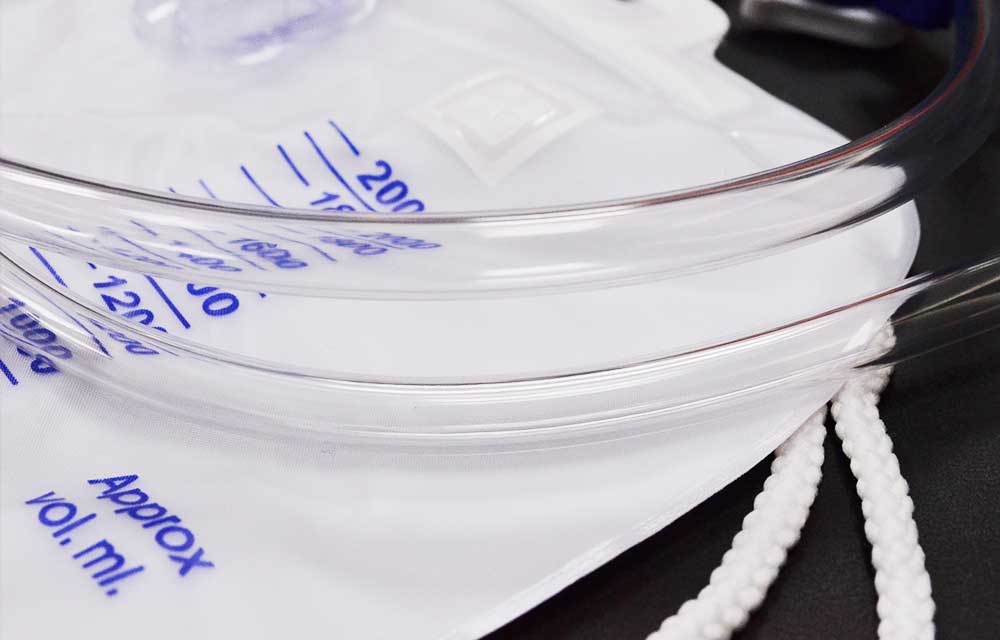

.SPIRAL MEDICAL TUBE–SPECIFIC MACHINE DESIGN

Extrusion medical tube can be loaded up to 5kg, new generation material EVA with better flexibility, gentleness, lightness, distance of rib reach 2.5mm doesn’t broken by pressed, meet ISO standard.

medical extrusion machine line introduce

Everplast medical tubing is high quality, stability, production tube with precised dimeter and min. tolerance of cutting length.

Everplast has customers for medical tubing production in Taiwan Turkey, Saudi Arabia, Mexico, Iran, Vietnam, Malaysia…, with social responsibility, Everplast will continue to develop the high quality machine for medical application.

main products

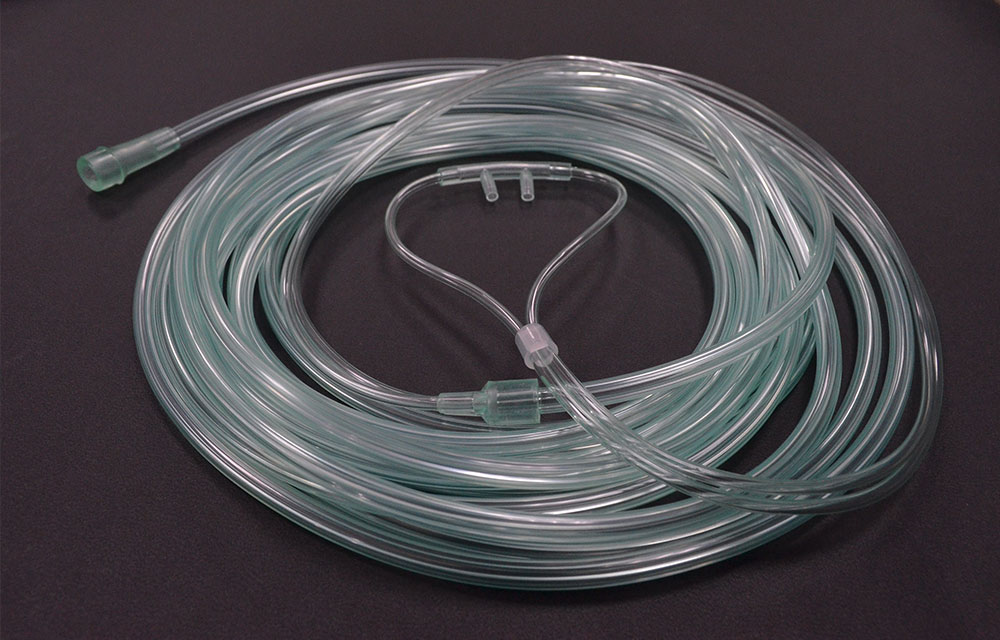

APPLICATION

Everplast Taiwan has many different kinds medical tube extrusion line for meeting different requirement, EMS-35, EMS-45, EMS-65, EMS-75 and others, Everplast’s machine can be for the different raw material (PVC/PE/TPU/PP/POE/EVA/FEP/PEEK…) for meeting different customer’s requirement.

Besides, the capacity of the machine can be from 2 – 80 kg/hr depends on the tube dimension, Medical tube does include the normal type, high speed type, precision type, spiral type and breathing tube, oxygen tube… are all meet medical grade application.

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.